Advancing Industrial Processes- The Role of Side Channel Vacuum Pump Technology

In the realm of industrial processes, efficiency is paramount. The evolution of vacuum pump technology has significantly contributed to enhancing productivity across various sectors. Among the diverse array of vacuum pumps available, side channel vacuum pumps stand out for their versatility and effectiveness. Let’s delve into the intricacies of side channel vacuum pump technology and its applications in modern industries.

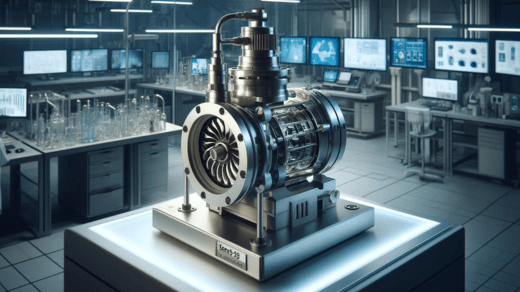

Understanding Side Channel Vacuum Pumps

At the core of side channel vacuum pumps lies a mechanism that utilizes centrifugal force to create vacuum pressure. Unlike traditional rotary vane vacuum pumps, which rely on sliding vanes, side channel vacuum pumps employ rotating impellers within a chamber to generate vacuum.

The Functionality of Dry Vacuum Pumps

One notable subtype within the realm of side channel vacuum pumps is the dry vacuum pump. As the name suggests, these pumps operate without the need for lubricants, making them ideal for applications where contamination is a concern. Industries such as pharmaceuticals and food processing benefit greatly from the cleanliness and efficiency offered by dry vacuum pumps.

Rotary Vane Vacuum Pumps: A Comparison

While rotary vane vacuum pumps have long been a staple in industrial settings, the emergence of side channel vacuum pumps has introduced a viable alternative. Unlike the oil-lubricated mechanisms of rotary vane vacuum pumps, side channel vacuum pumps offer oil-free operation, reducing maintenance requirements and environmental impact.

Exploring Oil Vacuum Pumps

In contrast to oil vacuum pumps, which necessitate regular oil changes and maintenance, side channel vacuum pumps provide a more sustainable solution. The absence of oil in side channel vacuum pumps eliminates the risk of oil contamination in the vacuum process, making them a preferred choice for industries prioritizing cleanliness and efficiency.

The Versatility of Side Channel Blowers

Beyond their application in vacuum systems, side channel blowers play a pivotal role in various industrial processes. From pneumatic conveying to wastewater treatment, these blowers offer reliable performance and energy efficiency. Becker-International stands at the forefront of delivering high-quality side channel blowers to meet the diverse needs of industries worldwide.

Applications of Side Channel Vacuum Pumps

The versatility of side channel vacuum pumps renders them indispensable across numerous industries. From packaging and printing to plastics manufacturing and woodworking, these pumps facilitate a wide range of processes with precision and reliability.

Enhancing Productivity with Side Channel Vacuum Technology

The adoption of side channel vacuum pump technology represents a strategic investment for industries seeking to optimize productivity and reduce operational costs. By harnessing the power of centrifugal force, these pumps deliver consistent vacuum performance while minimizing energy consumption.

Environmental Benefits of Side Channel Vacuum Pumps

In an era characterized by increasing environmental awareness, the eco-friendly attributes of side channel vacuum pumps are highly valued. With no oil lubrication required and lower energy consumption compared to traditional pumps, side channel vacuum pumps contribute to sustainability efforts across industries.

Innovations in Side Channel Vacuum Pump Design

Continuous advancements in side channel vacuum pump design have led to enhanced efficiency and reliability. Becker-International remains at the forefront of innovation, developing cutting-edge solutions to address evolving industry demands.

Maintenance Considerations for Side Channel Vacuum Pumps

While side channel vacuum pumps boast a reputation for robustness, proper maintenance is essential to ensure prolonged performance. Routine checks on impeller wear and motor efficiency are imperative to prevent downtime and optimize productivity.

Choosing the Right Side Channel Vacuum Pump

Selecting the appropriate side channel vacuum pump involves assessing factors such as required vacuum level, flow rate, and environmental conditions. With a diverse range of models available, consulting with experts at Becker-International can help identify the optimal solution for specific industrial applications.

Integration of Side Channel Vacuum Systems

Seamless integration of side channel vacuum systems into existing industrial processes is crucial for maximizing efficiency. Becker-International provides comprehensive support, from system design to installation and ongoing maintenance, ensuring smooth operation and minimal disruption.

Safety Considerations in Side Channel Vacuum Pump Operation

Maintaining a safe working environment is paramount when operating side channel vacuum pumps. Proper ventilation and adherence to safety protocols mitigate risks associated with vacuum systems, safeguarding personnel and equipment.

Future Trends in Side Channel Vacuum Technology

As industries continue to evolve, so too will side channel vacuum pump technology. Anticipated advancements include further improvements in energy efficiency, integration with IoT technology for remote monitoring, and enhanced material compatibility for specialized applications.

Training and Education in Side Channel Vacuum Pump Operation

Ensuring personnel are adequately trained in the operation and maintenance of side channel vacuum pumps is essential for optimizing performance and minimizing downtime. Becker-International offers comprehensive training programs to empower staff with the knowledge and skills required for efficient pump operation.

Global Reach of Side Channel Vacuum Pump Solutions

With a worldwide presence, Becker-International delivers side channel vacuum pump solutions to industries spanning the globe. From small-scale enterprises to multinational corporations, the reliability and performance of Becker pumps are trusted by customers worldwide.

Cost Efficiency of Side Channel Vacuum Pump Systems

While the initial investment in side channel vacuum pump systems may appear significant, the long-term cost savings justify the expenditure. Reduced maintenance requirements, energy efficiency, and increased productivity contribute to a favorable return on investment over the lifespan of the equipment.

Custom Solutions Tailored by Becker-International

Recognizing that every industrial application is unique, Becker-International offers custom solutions tailored to specific requirements. Whether it’s designing a vacuum system for niche applications or optimizing existing processes, rotary Vane Vacuum Pumps collaborates closely with clients to deliver optimal outcomes.

Collaborative Partnerships for Industry Advancement

The pursuit of excellence in industrial processes requires collaboration and innovation. Becker-International fosters partnerships with industry leaders, research institutions, and technology providers to drive continuous improvement and advance the capabilities of side channel vacuum pump technology.

In conclusion, side channel vacuum pump technology continues to revolutionize industrial processes, offering unparalleled efficiency, reliability, and sustainability. As industries embrace the advantages of side channel vacuum pumps, Becker-International remains committed to delivering innovative solutions that empower businesses to thrive in an ever-changing landscape. With a legacy of excellence and a vision for the future, Becker stands as a trusted partner in industrial advancement.