How Glass Shop Drawing Helps You Avoid Costly Errors in Curtain Wall and Storefront Projects

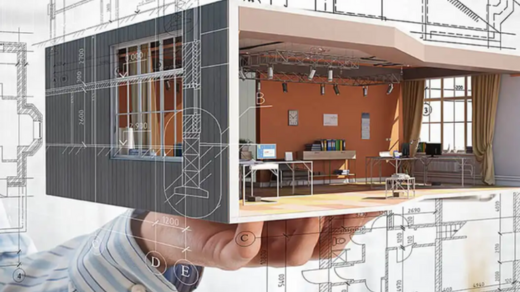

In the world of modern architecture and construction, glass is a fundamental material used in curtain walls and storefronts. These designs require precision and accuracy, as even small miscalculations can lead to costly errors. One of the most effective ways to ensure the successful execution of glass installations is through the use of glass shop drawings. These detailed technical drawings are critical to avoiding errors that could compromise the project’s quality, timeline, and budget.

What is a Glass Shop Drawing?

A glass shop drawing is a highly detailed, technical illustration that outlines the precise dimensions, materials, and installation specifications for glass components in a building project. It serves as a blueprint for fabricators, installers, and other stakeholders involved in the project, ensuring that every piece of glass fits perfectly within its designated space. These drawings are typically created after the architectural design has been finalized and the project is ready to move into the fabrication stage.

The Role of Glass Shop Drawings in Curtain Wall and Storefront Projects

Both curtain walls and storefronts are made up of large glass panels, framing systems, and supporting structures. The intricate nature of these installations requires precise measurements, material specifications, and compatibility with other elements of the building. Glass shop drawings play a crucial role in ensuring that each piece of glass is manufactured and installed correctly.

1. Precision in Measurements and Design

Curtain walls and storefront systems need to fit into pre-designed spaces with millimeter accuracy. Glass shop drawings detail every measurement, including the size, thickness, and cut of each glass panel. These drawings also include specifications for the type of glass used—whether it’s tempered, laminated, or insulated glass. Without accurate shop drawings, fabricators may encounter discrepancies between the design and the final product, leading to costly rework and delays.

2. Minimizing Errors in Fabrication

Glass fabrication involves cutting, shaping, and finishing the glass panels according to specific requirements. Even a minor mistake in the fabrication process, such as an incorrect dimension or a wrong cut, can cause significant delays and incur additional costs. By referring to precise glass shop drawings, fabricators are provided with clear instructions, reducing the chances of errors during manufacturing. These drawings also include details about the framing system and hardware, ensuring the glass fits into the supporting structure seamlessly.

3. Streamlining Installation

The installation of glass panels in curtain wall and storefront systems is a complex task that requires coordination between various construction teams. Glass shop drawings provide installers with a clear visual guide, outlining the exact location and positioning of each glass panel. This helps prevent mistakes during installation, such as incorrect alignment or improper attachment. When the installers follow the instructions in the shop drawings, the likelihood of rework is minimized, and the project stays on schedule.

How Glass Shop Drawings Prevent Costly Errors

The importance of glass shop drawings extends beyond the fabrication and installation process. They are instrumental in preventing costly errors in several key ways:

1. Avoiding Material Wastage

Incorrect dimensions or poor planning can result in the waste of valuable materials. Glass is expensive, and cutting and ordering incorrect sizes can lead to unnecessary purchases and disposal costs. By referencing glass shop drawings before any material is ordered, project teams can ensure that they only purchase the required quantities, minimizing wastage and saving money.

2. Ensuring Code Compliance

Building codes and safety standards must be adhered to when designing curtain walls and storefronts. Glass shop drawings are reviewed and approved by engineers to ensure that the materials and installation methods comply with relevant codes. This step is essential to prevent fines, penalties, and costly delays due to non-compliance with regulations.

3. Reducing Project Delays

A delay in the fabrication or installation phase of a project can be costly, leading to extended timelines and labor costs. Glass shop drawings are essential for planning and preparing materials well in advance of the construction phase. When all the necessary details are clearly outlined in these drawings, project teams can work more efficiently, avoiding delays caused by unforeseen complications or last-minute changes.

Conclusion

In curtain wall and storefront projects, the use of glass shop drawings is a vital component in ensuring the success of the project. These technical documents not only provide the necessary details for fabrication and installation but also help prevent costly errors by minimizing waste, ensuring compliance, and reducing the likelihood of delays. By leveraging the precision and clarity provided by glass shop drawings, construction teams can deliver high-quality results within budget and on time.